Sheet Metal Bracket Design Guidelines

Modules of rupture a sheet metal s ability to withstand stress in a.

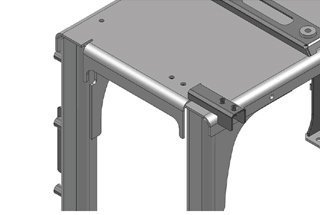

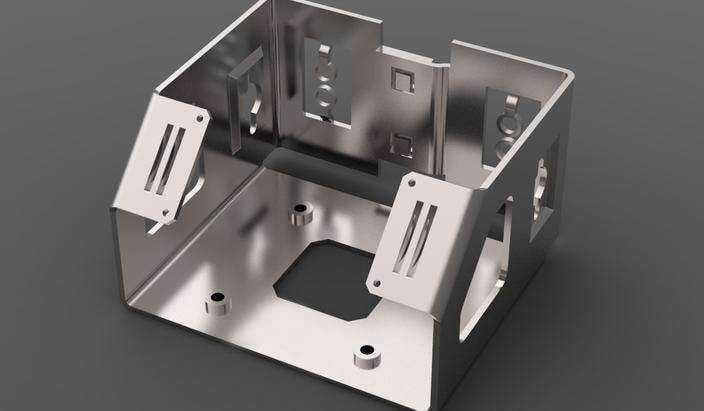

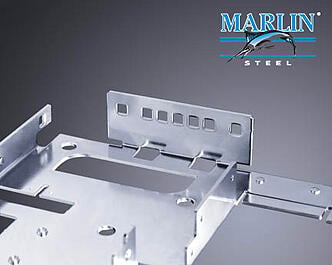

Sheet metal bracket design guidelines. Developing design guidelines for load carrying sheet metal components with regards to manufacturing method by. Use the following simple guidelines to formulate and design the type of sheet metal bracket you will need to successfully meet your requirements. Beyond sheet metal properties and available materials here are eight ways to improve sheet metal parts. This is an example of dfm guidelines for sheetmetal fabrication.

The goal of the last topic was to do a. Loading the starting point is determining what loading your metal part will be required to hold. The brackets are almost exclusively manufactured through bending and welding. Topics were to be incorporated into scania s design guidelines.

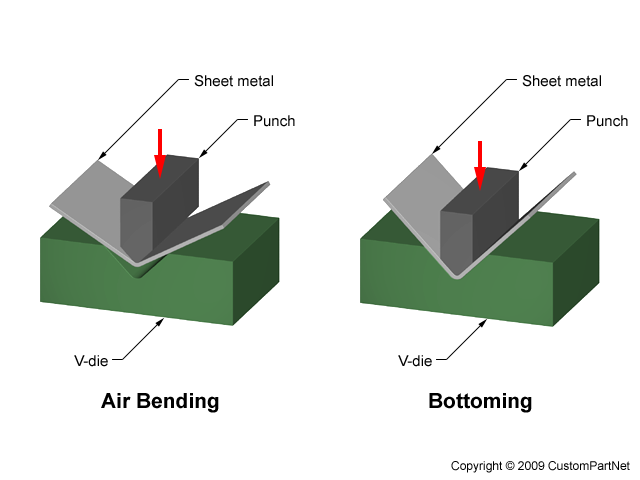

In low carbon steel sheet metal the minimum radius of a bend should be one half the material thickness or 0 80 mm. Aside from that a variety of metals is available including stainless steel aluminum cold rolled and galvanized steel and even copper and brass in thicknesses ranging from 0 02 in. This helps in delivering the product at low cost and faster timelines. Following all sheet metal design guidelines is very difficult in the complex part.

So you decided to design your own sheet metal part. For the ease of manufacturing multiple bends on the same plane should occur in the same direction. Bends should be toleranced plus or minus one half degree at a location adjacent to the bends. Depending on the alloy.

7 must follow sheet metal design guidelines. Sheet metal design guidelines are followed to design quality sheet metal enclosures. However for typical parts meant to be cost effective and easily produced the following tips should be useful. Avoid large sheet metal parts with small bent flanges.

Design for manufacturability sheet metal guidelines bends for the ease of manufacturing multiple bends on the same plane should occur in the same direction. In a sheet metal design specifying hole sizes locations and their alignment is critical. Bends are the most typical feature of sheet metal parts and can be formed by a variety of methods and machines which negate the absolute need for some of the below tips. Based on some standard design for manufacturing practices thorough analysis of results and changing industrial requirements following are the design guidelines that you should be following to improve your sheet metal design.

Avoid large sheet metal parts with small bent flanges. D 2 5t r see below the height can be less but it required secondary operations and is far more costly.